»Air Drive line lubrication not required.

»Compatible with all hydraulic fluids, plain water, distilled & deionized water, solvents, mild chemicals and most liquefied aerosol type gases.

»Range of models to provide up to 100,000 psi intermittent output pressure.

»Alternative gases that can drive the pump include nitrogen,vapor from liquefied gas,pipeline natural gas and sour natural gas with proper modifications.

»Hydraulic pressure is held without energy consumption.

»Explosion proof ,requires no electrical power or connections.

»Intrinsically safe.

»Compact, lightweight and weatherproof.

»Easy to adapt automatic controls.

»Contamination tolerant.

»Ideal for stop-start applications under full load.

»Special design can be chosen, this design can replace the high pressure seal without disassembling the pump.

Easy handling

1. Initial operation

The pump is prepared for operation manually:

»Connect supply lines (compressed air, suction and pressure lines).

»Set air drive pressure.

»Open compressed air supply slowly so that the high-pressure pump starts up .

2. Build up pressure

The pump technology executes all the steps for pressure build-up automatically:

»Automatic cycling of 4/2-way valve (spoolcycling valve) by means of air pulses from the pilot valve (2/2-way valve)

»Suction of medium.

»Optimum cycling conditions thanks to large cross-sections .

3. Achieve and hold pressure

The pump controls the processes of reaching and holding pressure.

»Pump automatically stops operating when the operating pressure is reached due to equilibrium of forces

»Pressure is held.

»Pressure holding phase with no energy consumption or heat generation .

»Pump restarted automatically if operating pressure drops .

Selection

The pump model is selected according to the use requirements. Such as output pressure, output flow, medium and

temperature, available air or gas drive pressure and flow. This guide will help you to pre-select the pump ideally suited

for your application. If you have specific questions, Please contact us. We urge you to provide us with details of the

duties you require from the pump, available air/gas drive pressure, and pressure/flow requirements, and we will

recommend a model and any corresponding accessories.

The series and its functions

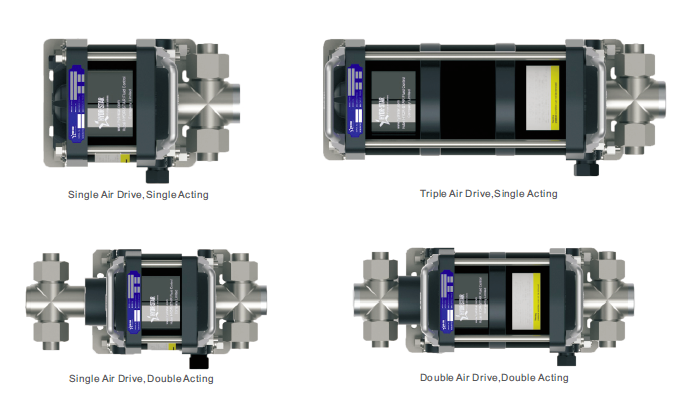

HYDR-STAR pumps offer the right solution for every application. They are suitable for different or stepped flow rates as well as for different maximum allowable operating pressures.HYDR-STAR pumps with two or three air drive sections reach the same final pressure as a HYDR-STAR pump with one air drive section with 1/2 or 1/3 of the air drive. Double-acting pumps increase the pump capacity by around 50% in comparison to single-acting pumps and reduce the pulsation equally.

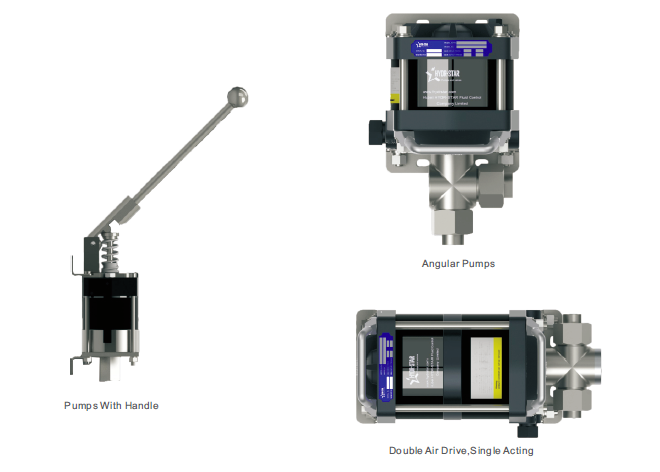

The following model variants are available depending on the series: